Precision Laminates Drive Motor Excellence

LS Laminates Provide Custom Stator and Rotor Solutions for Complex Designs

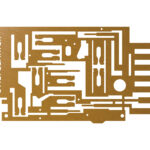

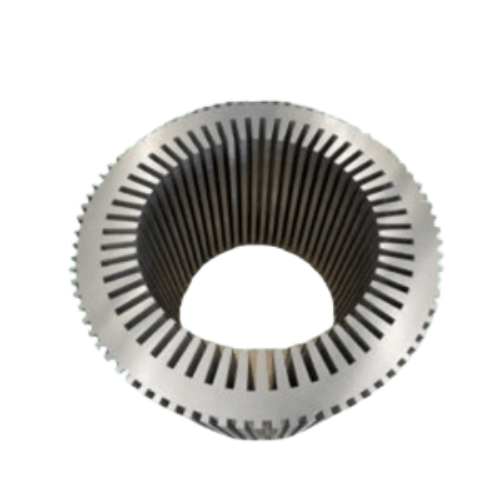

Precision Motor Laminations

High-precision laser-cut laminations for motors, serving the automotive, aerospace, and new energy industries.

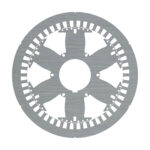

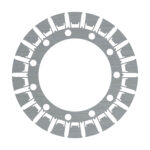

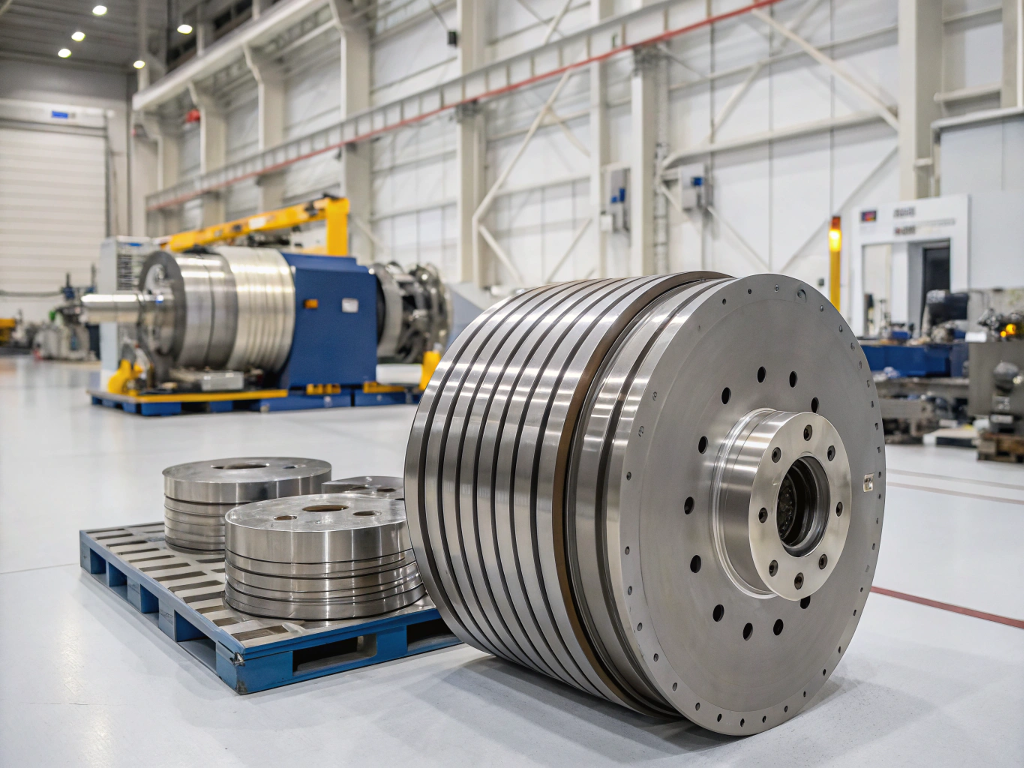

Rotor Laminations

High-precision rotor laminations designed to improve motor efficiency and reduce energy consumption.

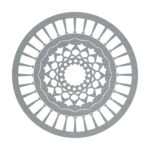

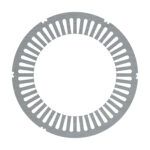

Stator Laminations

Premium stator laminations ensuring efficient motor operation for high-end applications.

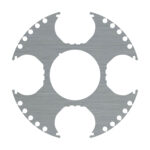

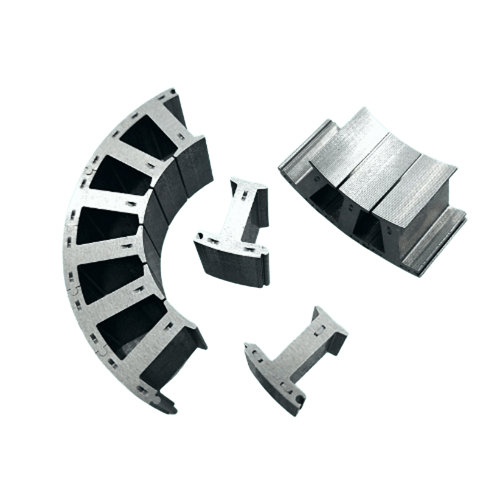

Segmented Laminations

We offer precisely crafted segmented stator stacks tailored to diverse electric motor needs.

World-Class Manufacturing

Equipped with German Stiefelmayer Effectie L laser cutting machines for superior precision and quality.

High processing accuracy

Achieves accuracy up to 0.01mm for complex geometries

Flexible production

suitable for small batches and prototypes

Efficient operation

dual-table design

Fast cutting

linear motor acceleration

Industry Pain Points & Our Solutions

Leveraging advanced German technology and expertise to solve complex manufacturing challenges across industries.

Motor Manufacturing

Pain Points:

Mass production challenges with balancing high precision requirements and material waste while maintaining cost-effectiveness and meeting delivery schedules.

Our Solution:

Advanced laser cutting technology optimizes material utilization while maintaining precision, reducing costs without compromising quality.

Automotive Industry

Pain Points:

The long sample production cycle makes it difficult to quickly verify and iterate.

Our Solution:

Provide a sample production line review within 24 hours to help accelerate the research and development process and product iteration.

Aerospace & Defense

Pain Points:

Demanding precision requirements for small batch production with strict process control needs.

Our Solution:

High-precision German Stiefelmayer laser cutting ensures exceptional accuracy and reliability for critical components.

Our Customers

Our Partners and Customers

At LS Lamination, we provide customized motor laminate solutions to major motor manufacturers, electric vehicle manufacturers, new energy companies, and research institutions around the world. Our products and services have been widely used in many industries, helping our customers achieve efficient motor manufacturing and innovation.

Scientific Research Institution

Cooperate with scientific research institutions to provide customized samples to help develop the next generation of motor technology.

Electric Vehicle Manufacturers

Provides high-precision stator and rotor laminations for new energy vehicle motors, helping electric vehicles to perform efficiently.

Aerospace and Defense Industry

We provide lightweight, high-performance motor components for aerospace and defense companies to ensure that they meet demanding design requirements.

New Energy Industry

We provide precision motor laminations for new energy enterprises such as solar and wind power, promoting the development and application of sustainable energy.

Motor Manufacturer

Helps motor manufacturers improve motor efficiency and optimize production processes.

Customer Success Stories

Discover how LS Lamination helps leading manufacturers worldwide achieve excellence in motor manufacturing through precision engineering and innovative solutions.

Advanced Manufacturing

State-of-the-art Stiefelmayer Effectie L laser cutting machine from Germany

High Precision

Industry-leading cutting accuracy for complex designs

Custom Solutions

Specialized prototyping services for unique requirements

Global Excellence

Trusted by leading companies across USA, Australia, Thailand, South Korea, and Germany

What Our Clients Say

Our Commitment & Service Guarantee

As a leading manufacturer of stator and rotor laminations, we pride ourselves on delivering exceptional service and maintaining the highest standards of quality.

Electric Motor lamination FAQs

What Is The Motor Core Lamination?

Motor lamination is an essential component of electric motors. It refers to thin components which make up the core of the motor.

These laminations consist of thin metal sheets stacked, welded, or bonded to form the motor’s core.

Motor lamination is important in many electrical applications and is used in everything from electric vehicles to generators.

What Are Common Materials Used In Motor Core Lamination Stacks?

When it comes to motor core lamination, electrical steel is the most common material that is used. This is because electrical steel has many magnetic properties that make it ideal for motor lamination.

These properties include high permeability, low coercivity, and high saturation flux density.

Other materials that can be used in motor core lamination include nickel alloy and cobalt alloy.

What Are The Applications Of Motor Cores?

Motor cores are used in generators, transformers, and other power electronics devices to help provide efficient power conversion and control.

In addition, they can be found in electric vehicles and home appliances such as washing machines and refrigerators.

Due to their robustness and ability to withstand large amounts of heat generated by electricity flowing through them, motor cores have become essential for many industrial machines where reliability is crucial.

How To Find A Reliable Motor Core Lamination Stacks China Manufacturer?

Finding a reliable motor core lamination China manufacturer is not as easy as it may sound. It requires research and due diligence to ensure your supplier can meet your needs.

Here are some tips to help you find the best motor core lamination China manufacturer for your business:

First, check the reliability of any potential suppliers. You can do this by looking at customer reviews, trade association membership, and references from other companies that have used their services. Ensure you clearly understand what materials they use and how long it takes them to deliver products.

Additionally, ask about quality control processes and safety standards to ensure they adhere to industry regulations.

Second, consider cost efficiency when choosing a motor core lamination China manufacturer.